CONODENT Instrument Care & Maintenance Guide

Preserving Precision, Ensuring Safety

To maximize the lifespan of your CONODENT premium instruments and ensure the safety of your patients, follow this standardized reprocessing protocol. Proper care prevents corrosion, maintains sharpness, and ensures smooth mechanical function.

1. Point-of-Use Preparation

- Immediate Rinse: Rinse instruments under warm running water immediately after use to remove blood, tissue, and debris.

- Avoid Drying: Never allow biological contaminants to dry on the instrument. If immediate cleaning isn’t possible, use a pH-neutral enzymatic foam or gel to keep debris moist.

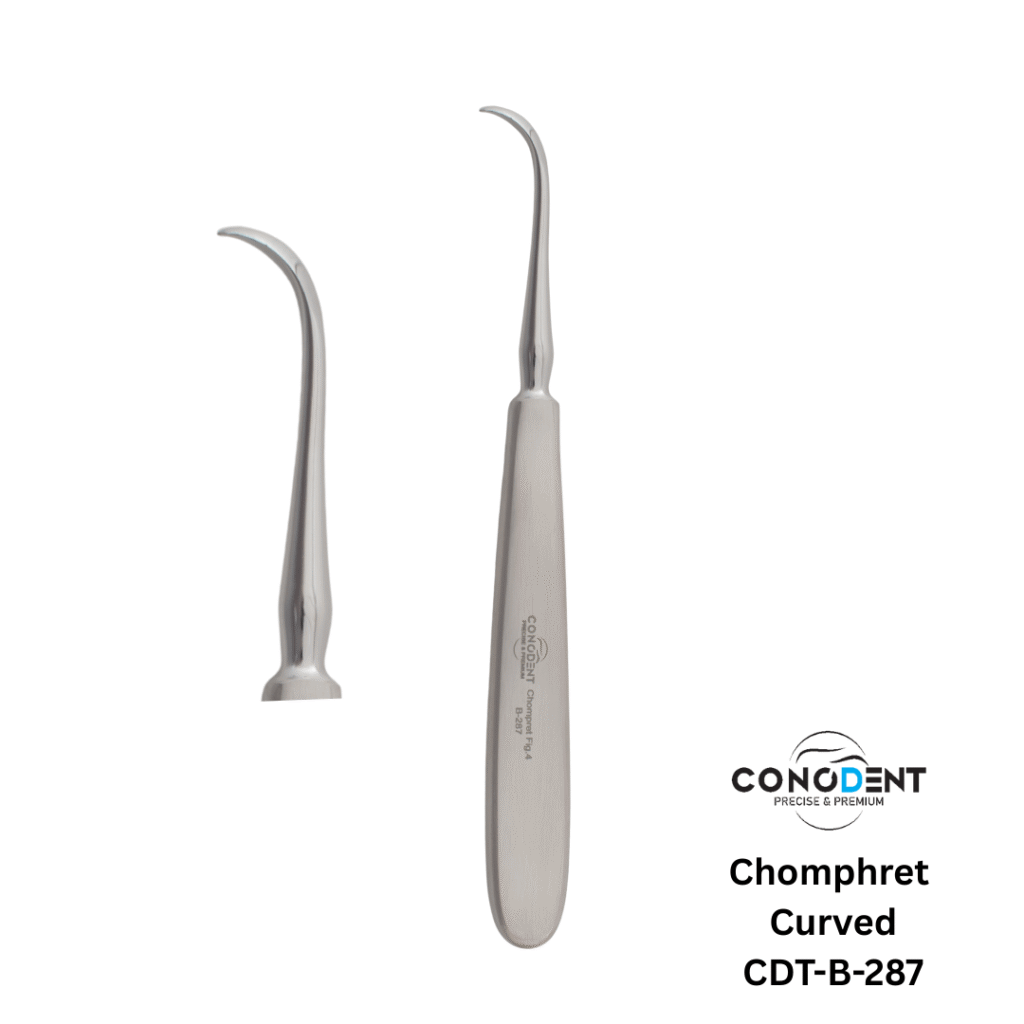

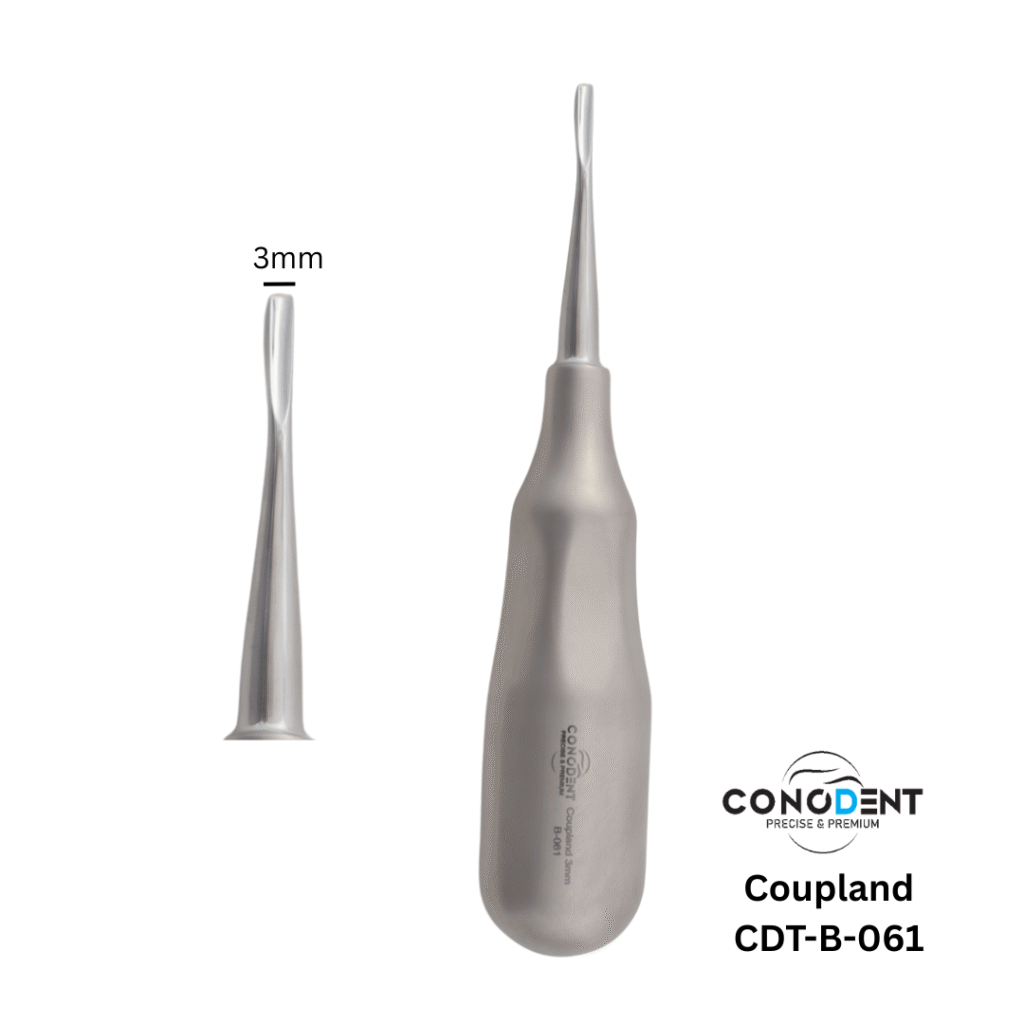

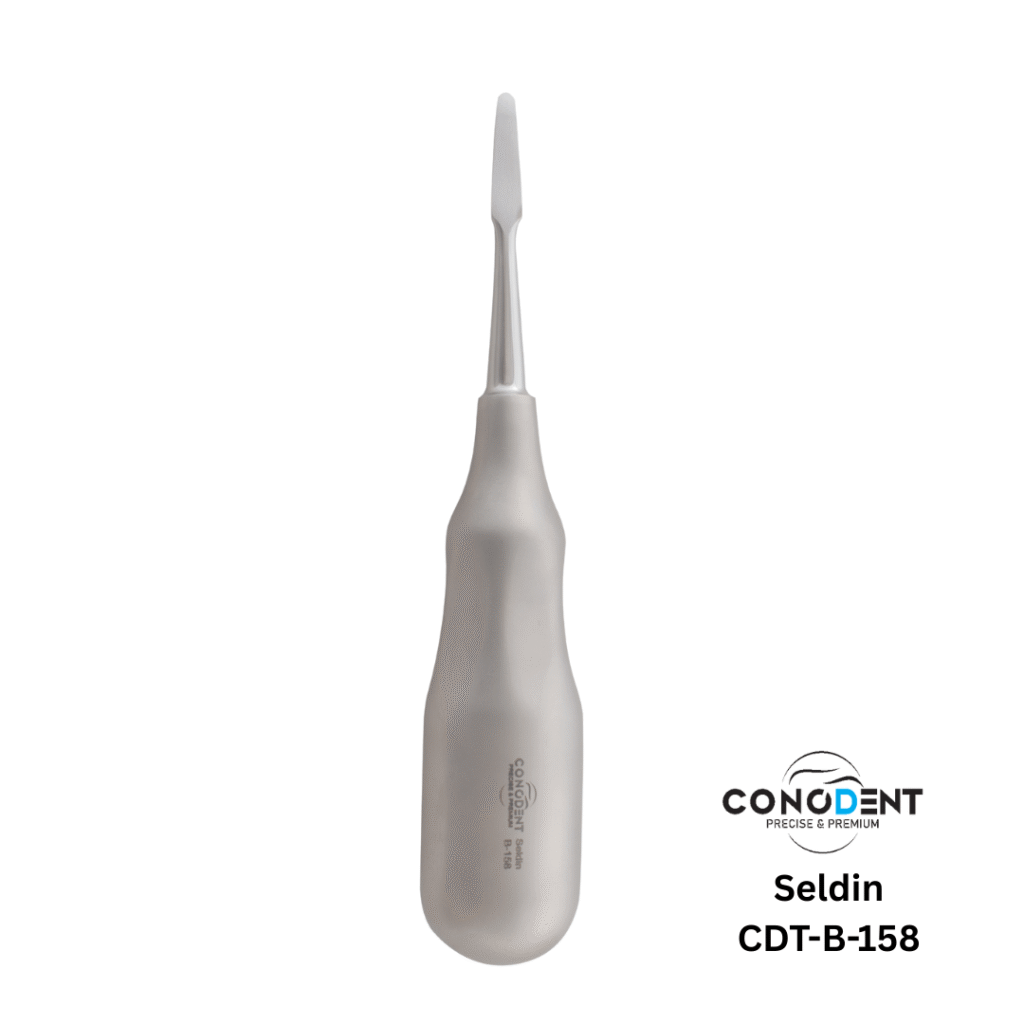

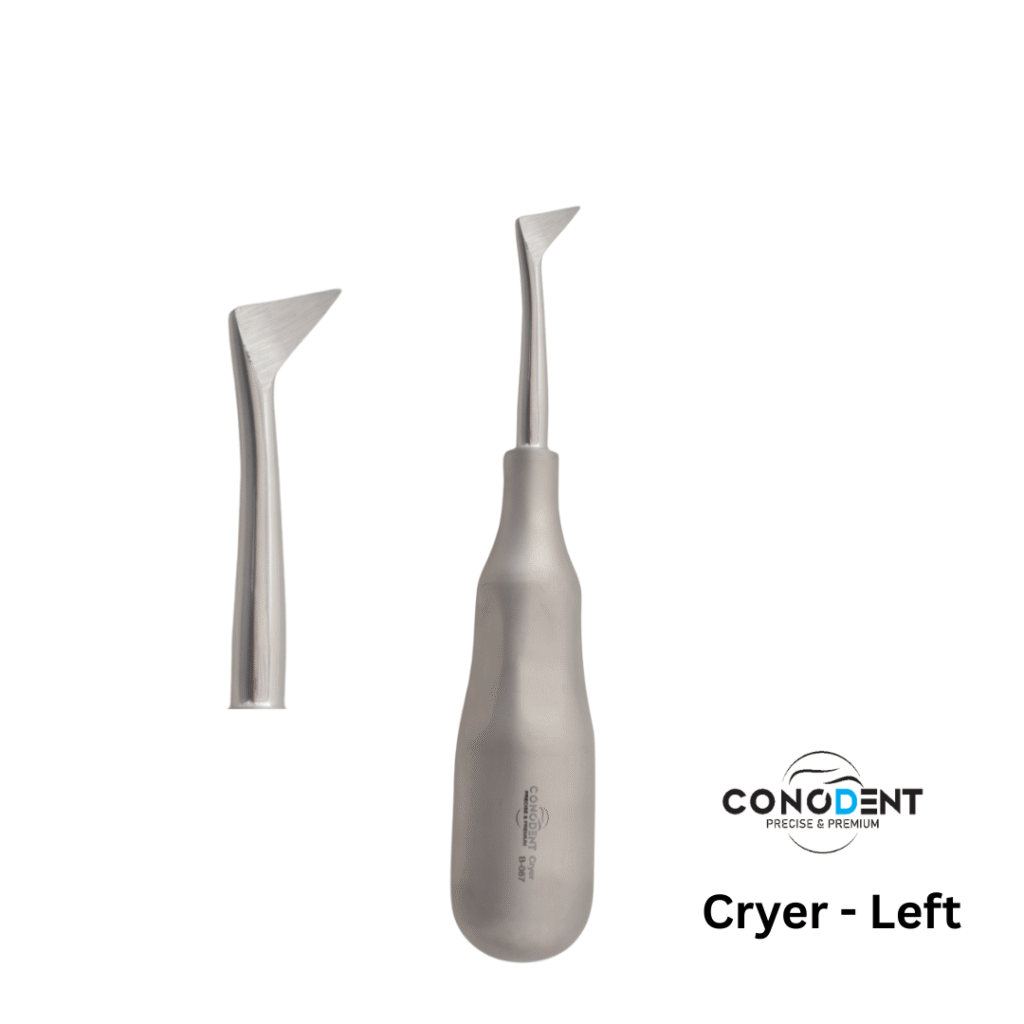

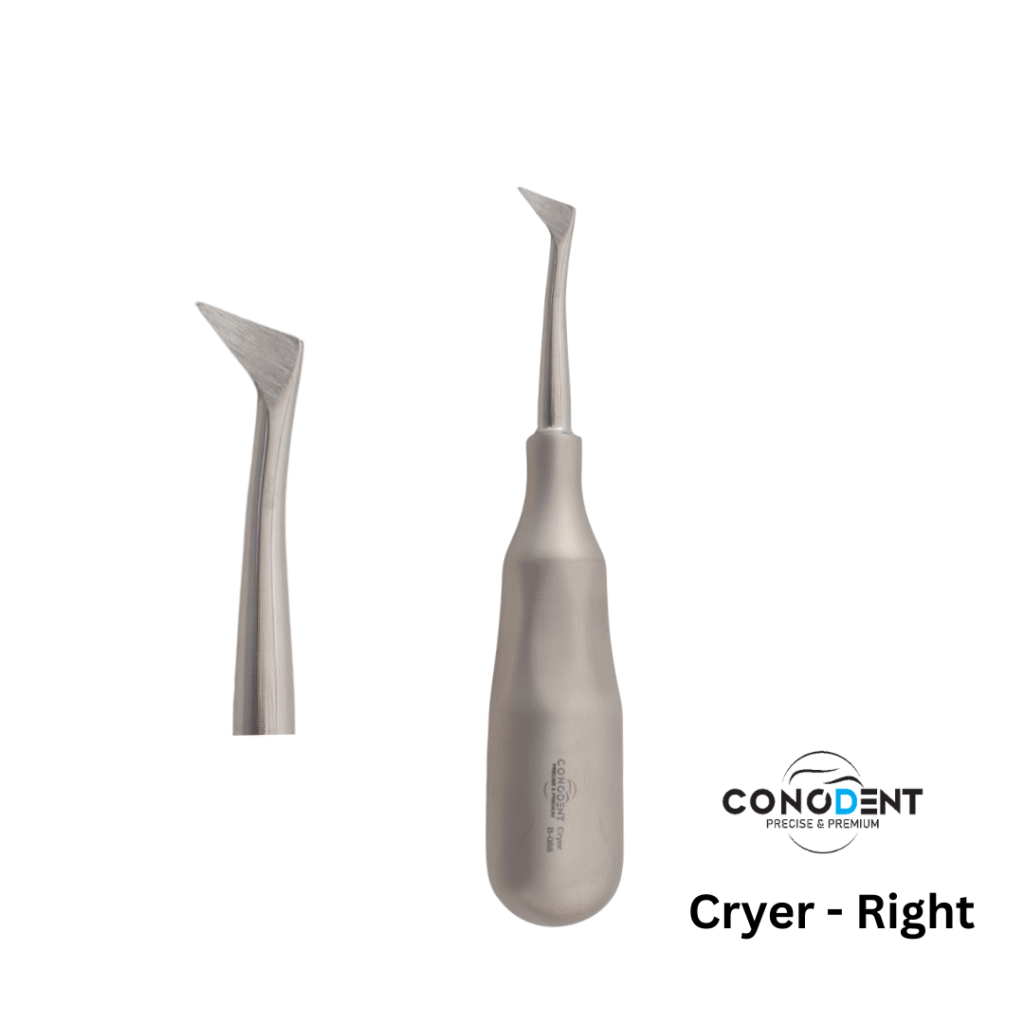

- Separation: Keep delicate items (Periotomes, Composite instruments) separate from heavy tools (Forceps, Elevators) to prevent tip damage.

2. Cleaning & Disinfection

- Ultrasonic Cleaning: This is the most efficient method. Use a pH-neutral detergent and ensure instruments are in the open position.

- Note: Do not mix dissimilar metals (e.g., chrome-plated and stainless steel) in the same cycle to avoid galvanic corrosion.

- Manual Cleaning: Use only soft nylon brushes. Never use steel wool or wire brushes, as these will damage the protective “passive layer” of the steel and lead to “pitting.”

- Drying: This is the most critical step. Thoroughly dry instruments before sterilization. Moisture trapped in joints or box locks is the primary cause of rust during autoclaving.

3. Inspection & Lubrication

- Visual Check: Inspect tips for sharpness, alignment, and any signs of “spotting” or corrosion.

- Lubrication: For all hinged instruments (Forceps, Needle Holders, Scissors) and spring-action tools (Crown Removers), apply a medical-grade, water-soluble lubricant (Instrument Milk).

- Note: Do not use industrial oils; they will interfere with the sterilization process.

4. Sterilization (Autoclaving)

- Parameters: Follow standard steam sterilization cycles (typically 134°C for 3–5 minutes).

- Loading: Do not overload the autoclave. Ensure steam can circulate freely around every instrument surface.

- Cassette System: We recommend using CONODENT Stainless Steel Cassettes to protect delicate tips from rattling and breaking during the cycle.

Quick Troubleshooting: Spots vs. Rust

| Appearance | Cause | Solution |

| Brown/Orange Stains | High pH in water or dried blood. | Use distilled water and neutral detergents. |

| Dark Black Spots | Ammonia in cleaning agents or improper drying. | Ensure pH-neutral chemicals; dry immediately. |

| Bluish/Grey Tint | Excessive “Instrument Milk” or hard water. | Follow lubricant dilution ratios; use softened water. |

The “CONODENT” Golden Rules

- Neutral pH Only: Always use chemicals with a pH between 7.0 and 8.5.

- Open Joints: Sterilize forceps and scissors in the open/unlocked position.

- No Tap Water: Use distilled or deionized water for the final rinse and autoclave reservoir to prevent mineral scaling.